كيف يمكن لآلة ثني كهربائية بالكامل أن تمكّن المبتدئين من التعامل مع عملية الثني بسهولة؟

Jan 30, 2026

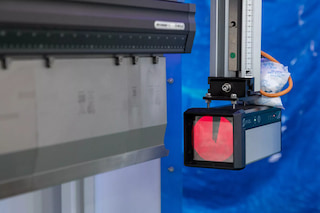

المفهوم الأساسي: لماذا تُعتبر الأشياء نقية؟ آلة ثني كهربائيةهل هو أكثر سهولة في الاستخدام للمبتدئين؟1. عملية مبسطة: التحكم الكهربائي الكامل يلغي الحاجة إلى المعايرة الهيدروليكية المعقدة، مما يؤدي إلى تقليل الضوضاء وتوليد الحرارة.2. الحماية الذاتية الدقيقة: يتحكم نظام المؤازرة بدقة في موضع وسرعة المنزلق، مع دقة تكرار عالية للغاية. بمجرد ضبطه، لا داعي للقلق بشأن الإنتاج بكميات كبيرة.3. السلامة والذكاء: عادةً ما تكون مزودة بواجهة رسومية أكثر سهولة في الاستخدام، ووظيفة اليد المضادة للتصادم، وتنبيهات التشغيل الخاطئ، وما إلى ذلك.4. لا يحتاج إلى صيانة: لا يتطلب زيت هيدروليكي، مما يقلل من خطوات الصيانة ومخاطر التلوث. طريقة من أربع خطوات للمبتدئين للبدء بسهولةالخطوة الأولى: الاستعدادات قبل البدء - السلامة والفهماقرأ الدليل: اقضِ 30 دقيقة في تصفح دليل تشغيل المعدات لفهم زر التوقف الطارئ والأزرار المختلفة ومناطق واجهة المستخدم.ارتدِ معدات الوقاية: تأكد من ارتداء قفازات واقية (لمنع الجروح)، ونظارات واقية (لمنع تناثر برادة الحديد)، وأحذية السلامة.تعرّف على قطعة العمل الخاصة بكالمادة: ما هي؟ على سبيل المثال: ألواح فولاذية مدلفنة على البارد، فولاذ مقاوم للصدأ، ألومنيومالسُمك: ما مقداره؟ (مثلاً 1.5 مم)زاوية الانحناء: ما هي الزاوية التي يجب أن تنحني بها؟ (مثلاً 90 درجة)الحجم: ما هو طول الحافة المنحنية؟ الخطوة الثانية: إعداد الجهاز - استخدام النظام الذكيهذه هي الخطوة الأكثر أهمية. نظام التحكم في آلة الثني الكهربائية الخالصة هو "مساعدك الأقوى".معلمات الإدخال: على شاشة اللمس الخاصة بالتحكم، حدد "برنامج جديد" أو "معالجة فردية"، ثم أدخل ما يلي:نوع المادةسمك المادةيتم اختيار فتحة الأخدود على شكل حرف V للقالب السفلي (بشكل عام، من 6 إلى 8 أضعاف سمك اللوحة؛ على سبيل المثال، يتم اختيار أخدود على شكل حرف V بطول 12 مم للوحة بسمك 1.5 مم). يحتوي النظام على قيم موصى بها.زاوية الانحناء المستهدفةطول الانحناءدع الجهاز يقوم بالحساب تلقائيًا: اضغط على مفتاح "البرنامج" أو "الحساب"، وسيقوم الجهاز بالحساب تلقائيًا:وضع القالب السفليالمركز السفلي للقالب العلوي (عمق المنزلق)الضغط المطلوبوضعية التوقف الخلفيقم بتركيب القالبإيقاف التشغيل! تأكد من توقف الجهاز تمامًا.وفقًا لاقتراحات النظام، حدد القالب العلوي المناسب (سكين حاد، سكين منحني، إلخ) والقالب السفلي (أخدود على شكل حرف V).استخدم أداة (مفتاح ألين) لتثبيته بإحكام، ولكن لا تفرط في شده. الخطوة 3: تجربة الطي والضبط الدقيق - تحقق بصبرلإجراء "الطي التجريبي": ضع قطعة من المواد الخردة من نفس المادة والسمك مثل قطعة العمل، واضغط على مفتاح القدم أو انقر فوق "دورة واحدة" لإجراء الطي التجريبي.قياس الزاوية: استخدم مقياس الزاوية لقياس زاوية قطعة العمل المراد طيها.إذا كانت الزاوية كبيرة جدًا (مثل 95 درجة): فهذا يشير إلى أن الانحناء غير كافٍ. أضف "عمق الانحناء" أو "قيمة التصحيح" (على سبيل المثال، +0.1 مم) على شاشة التحكم.الزاوية صغيرة جدًا (مثل 85 درجة): يشير ذلك إلى أن الانحناء عميق جدًا. قلل "عمق الانحناء" (على سبيل المثال، -0.1 مم) على لوحة التحكم.اضبط المصد الخلفي: إذا كان وضع الانحناء غير صحيح، فقم بضبط الوضعين الأمامي والخلفي للمصد الخلفي.الضبط الدقيق المتكرر: عادةً، بعد محاولتين أو ثلاث من الثني والضبط الدقيق، يمكن الحصول على زاوية مثالية. تكمن ميزة آلة الثني الكهربائية بالكامل في حفظ المعايير المُعدّلة تلقائيًا، ويمكن استدعاؤها مباشرةً عند ثني المنتج نفسه في المرة القادمة. الخطوة الرابعة: الانحناء الرسمي والإنتاج الضخمتم التأكد من صحة النتائج: زاوية وحجم قطعة الاختبار المطوية مؤهلة تمامًا.ثني الدفعاتضع قطعة العمل بالقرب من الحاجز الخلفي.ضع كلتا يديك على جانبي قطعة العمل. لا تضعهما أسفل القالب.اضغط على مفتاح القدم لإكمال عملية الانحناء.كرر العملية واستمتع بدقة التكرار الثابتة للجهاز.فحص العينة الأولى: قم بإجراء فحص عشوائي منتظم للعينة الأولى أثناء إنتاج الدفعة للتأكد من عدم وجود أي انحرافات. هل لديك أسئلة حول معايير هذا النموذج؟انقر هنا لاستشارة كبير مهندسينا التقنيين.الهاتف: +86-18855551088البريد الإلكتروني: Info@Accurl.comواتساب/جوال: +86-18855551088